Understanding the Proctor Test: The Backbone of Soil Compaction

March 02, 2025

A strong foundation is crucial in construction. One of the most important steps in achieving this is proper soil compaction, and that’s where the Proctor test comes into play. Named after engineer R.R. Proctor, this construction materials testing laboratory test helps determine the optimal moisture content for soil to reach its maximum density. In simple terms, it ensures that soil is compacted efficiently to prevent future settling and structural issues.

What is the Proctor Test?

The Proctor test is a standard method used in construction materials testing (CMT) to analyze the relationship between moisture content and soil density. The goal is to find the moisture content that gives the best compaction.

There are two types of Proctor tests:

- Standard Proctor Test (ASTM D698) – Uses a 5.5 lb hammer dropped from 12 inches to compact soil in three layers, each receiving 25 blows. The Standard Proctor Test was developed by Ralph R. Proctor in 1933.

- Modified Proctor Test (ASTM D1557) – Uses a 10 lb hammer dropped from 18 inches, applying more force. The Modified Proctor Test was introduced by the U.S. Army Corps of Engineers in 1948 to accommodate the need for projects requiring greater compaction like airports and highways.

The main difference between the Standard Proctor Test (ASTM D698) and the Modified Proctor Test (ASTM D1557) is the force applied to the soil sample:

| Feature | Standard Proctor (ASTM D698) | Modified Proctor (ASTM D1557) |

|---|---|---|

| Introduced By | R.R. Proctor | U.S. Army Corps of Engineers |

| Year Introduced | 1933 | 1948 |

| Hammer Weight | 5.5 lbs (2.5 kg) | 10 lbs (4.5 kg) |

| Drop Height | 12 inches (305 mm) | 18 inches (457 mm) |

| Number of Layers | 3 | 5 |

| Blows per Layer | 25 | 25 |

| Effort/Force | ~12,400 ft-lbf/ft³ | ~56,000 ft-lbf/ft³ |

| Max Dry Density | Lower | Higher |

| Optimum Moisture Content | Higher | Lower |

Why is the Proctor Test Important?

Proper soil compaction is crucial for the success and longevity of any construction project. The Proctor test helps ensure that:

- Structures Have a Stable Base – It reduces the risk of shifting and settlement, which can cause cracks or failures.

- Load-Bearing Capacity is Maximized – Essential for roads, buildings, and embankments.

- Water Drainage is Controlled – Prevents erosion and weak foundations caused by water buildup.

- Projects Meet Construction Standards – Many building codes require specific compaction levels before work can continue.

Instruments Used in the Proctor Test

Some of the specialized instruments used in the Proctor test to ensure accurate soil compaction include:

- Proctor Mold and Collar – A cylindrical metal mold where the soil sample is compacted.

- Compaction Hammer – A manually operated drop hammer used to compact the soil sample. Alternatively, an automatic mechanical compactor can be used to get consistent and repeatable compaction.

- Drying Ovens – Used to determine the soil’s water content accurately.

- Weighing Scale – Measures the mass of soil before and after compaction to calculate density.

- Straight Edge and Spatula – Levels the compacted soil for precise measurement.

- Sieve Set – Classifies soil particles by size before testing.

How is the Proctor Test Conducted?

- Soil Sample Preparation – A representative soil sample is collected and air-dried.

- Compaction in a Mold – The sample is placed in a cylindrical mold and compacted in layers using a standard hammer.

- Weight and Density Measurement – The weight of the compacted soil is measured, and the dry density is calculated.

- Multiple Tests – The process is repeated with varying moisture contents to find the optimum moisture content (OMC) that results in the highest dry density.

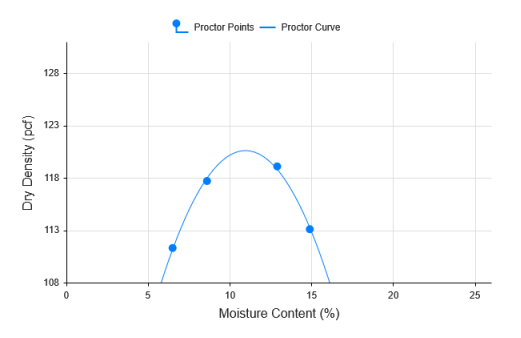

- Moisture-Density Curve – A graph is plotted to determine the peak dry density, indicating the best moisture content for compaction.

How does LIMS help with Proctor Testing?

A construction materials testing software with Laboratory Information Management System (LIMS) enhances the efficiency of Proctor testing by:

- Ensuring Compliance – Maintains ASTM and AASHTO standards by enforcing proper test procedures.

- Generating Moisture-Density Curves – Automatically plots test results for quick analysis.

- Managing Samples and Projects – Tracks soil samples, linking them to specific projects and clients.

- Providing Real-Time Access – Enables engineers and project managers to review results instantaneously.